our Services

Advanz Quality Services & Engineering PTE LTD is a leading provider of Quality Control Testing and Management Services in Singapore. Our engineers provide air quality testing, helium leak testing, and borescope inspection services to a variety of industries, including but not limited to electronics, chemical, construction, aerospace, F&B, life sciences and biomedical.

Process & Compressed - Air Quality Test

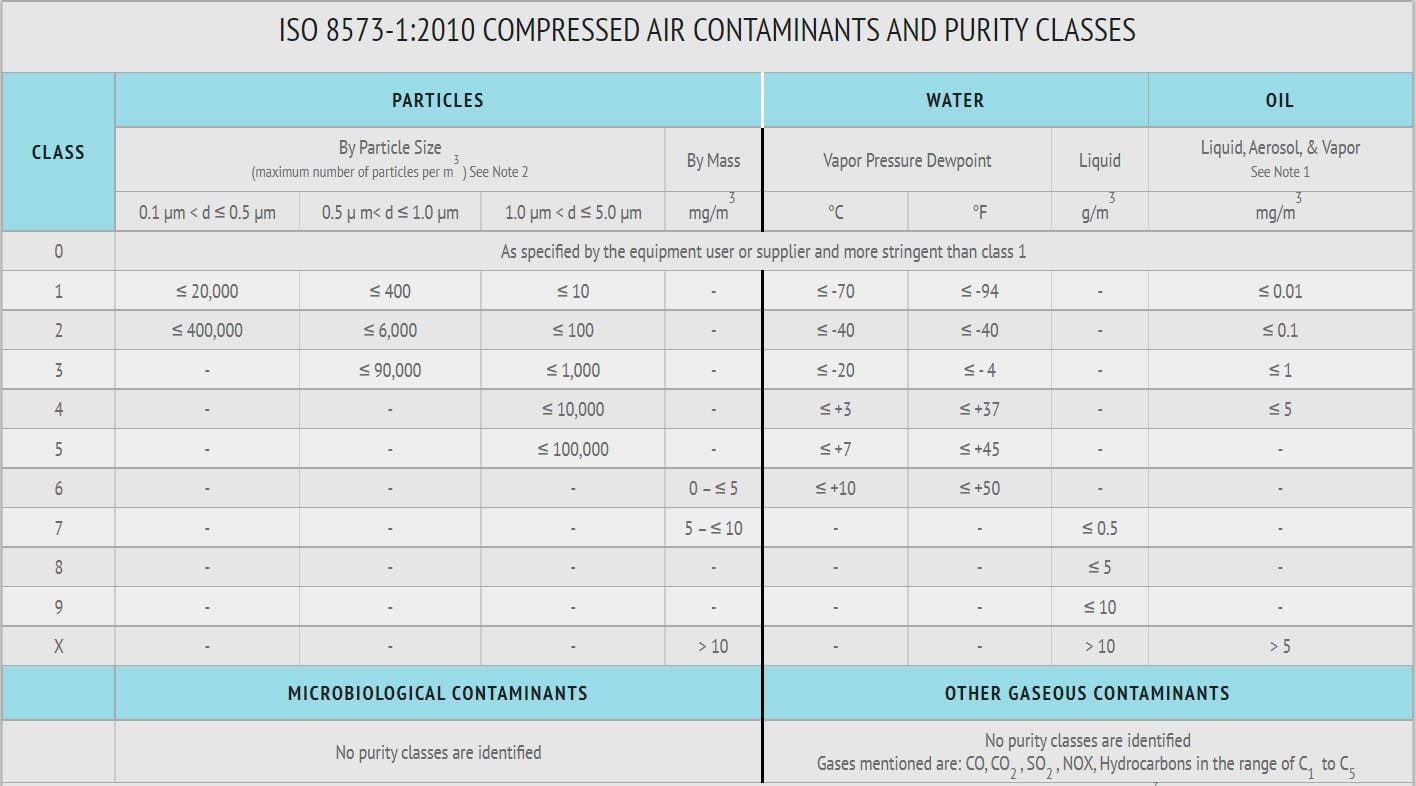

Air Quality Testing is performed to certify or validate the purity class of process gases with reference to ISO 8573-1:2010 or Customer’s requirement which summarises into the following three categories:

- Particle – impurities as small as 0.1 microns

- Water – moisture in the form of pressure dewpoint

- Oil – in the form liquid, aerosol and vapor

Particles, water, and oil in are seen as impurities that will contaminate downstream systems which leads to rejection of end-products and also the early failure of high-end machineries.

Conducting periodic Air Quality Testing will allow early detection of potential problems and at the same time provide peace of mind while maintaining a high-quality production.

- Process Air System within customer specifications.

- Compressed Air System (ISO 8573-1:2020):

Compressed Air Testing is performed for establishing the purify class / validation of process air system using the International Standard ISO 8573-1:2020 which summarises into different classes of Dew Point Measurement, Particle Count Measurement and Oil Mist.

Helium Leak Detection with the capability to find and quantify leak rate as minute as 1 x 10-11 std cc/sec. With our extensive industry experience, we are able to meet any customer requirement.

With state-of-the-art borescope equipment, we able to clearly identify weld defects and chokes in pipeline that help to solve quality issues.

It is a Visual Inspection that require experience and at least ASNT Level II certified inspector to carry out interpretation of the video images.

Particles varies in sizes present in a Compressed Air System are contaminants that required a long duration and a large amount of purging gas.

A pipeline with high contaminants will contaminate the production floor, hence causing poor quality of products produced.

Dew Point is important for Microelectronics/Pharmaceutical Industries as high Dew Point could cause equipment to be malfunctioned and certain water sensitive processes that require compressed air may have a specific dryness specification.

Pharmaceutical processes which require high purity may treat water vapor as contaminants.

Oil Mist Sampling is collected at End of Line of Compressed Air System to determine the oil content of the air. The oil sample collected on the membrane filter was dissolved in a fluorocarbon solvent and analysed by Infrared Spectrophotometry.

A flowmeter is used with PVC membrane filter connected to the sampling point. Sample for 2 hours at 2L per minute and the sampling filter will be sent for lab analysis using the Horiba Oil Analyzer

CDA Piping System Design

We provide system design services from conceptual design stage, all the way until handover stage to client. That’s not all, we can provide additional services below which will provide the client a peaceful state of mind when engaging us.

1) Orbital & Manual Welding

2) Design and Build

3) Procurement of materials

4) Fabrication and Installation

5) Quality checks for the system